Choosing a membrane with proper material of construction (MOC), size of pores (cut off), and configuration (spiral or tubular) is the first step to getting accurate laboratory filtration results. We can easily differentiate between the clean and dirty (high solids load) samples just by visual observations and then choosing the correct membrane. You will get better results consistently, whether you are purifying proteins or preparing the samples for the analysis.

One wrong membrane choice can destroy months of research data and waste thousands in chemical reagents. The membrane you choose today determines whether your experiments succeed or fail tomorrow. Master this critical decision, and transform your lab’s efficiency forever.

Different Types of Membranes

Microfiltration (MF)

It works with pores that are 0.1 to 5.0 microns in diameter. This process is quite good at getting rid of bacteria, particulates, and suspended materials. MF is often used in labs to clean up and sterilise samples. Also, can be used for concentrating the biomass in case of probiotics application.

Ultrafiltration (UF)

This works in the range of 1.0 to 800 kDa cut off helping to concentrate proteins, and organise molecules by weight. According to the lab ultrafiltration membrane guide, UF is the finest approach to deal with biomolecules as it has the widest range to handle a variety of solutions from protein purification in pharma & biotech, vaccine processing, dairy whey protein concentration

Nanofiltration (NF)

It fits in the gap between UF and reverse osmosis spanning from 100 to 600 Da. It works so effectively at cleaning and getting rid of monovalent salt because it separates molecules based on their size and charge.

Reverse Osmosis (RO)

It separates things the best at 0.001 microns (< 100 Da). RO is used in labs to make water that is very pure and to get rid of dissolved salts in solutions.

Specialty Membranes

They come in ceramic alternatives for tough chemical environments and special polymer membranes for certain uses.

Important Factors to Consider

The chemical makeup of your solution affects membrane interaction.

- PTFE membranes should be used for strong acids or bases, whereas cellulose acetate or PES membranes should be used for water-based solutions.

- Think about the particles you want to hit. Microfiltration and ultrafiltration labs determine which one to employ based on the size of the particles: MF is for bacteria and bigger particles, while UF is for proteins and viruses.

- The flow rate requirements impact the membrane area to use. For greater volumes, you need either bigger membrane widths or more than one module.

- The choice of membrane material depends on the temperature and pH. Under very bad conditions, some polymers break down.

- The membrane module has a membrane, spacer, glue and permeate tube. The compatibility is known only for membranes and not for other components in the module.

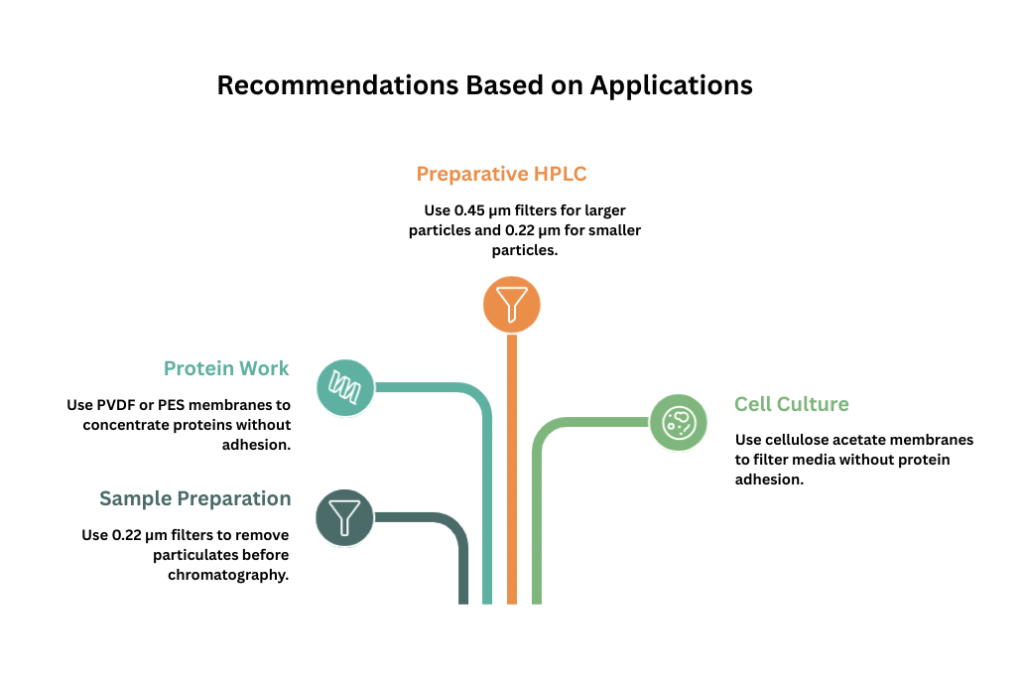

Recommendations Based on Applications

Sample Preparation: For sample prep before chromatography, use 0.22 μm filters for membrane filtering. This gets rid of particulates that could hurt columns.

Protein Work: PVDF and PES membranes are the best membrane filters for concentrating proteins. These materials don’t attach to proteins very well and maintain their biological activity.

Preparative HPLC: For systems that use bigger particles, pre-filter samples with 0.45 μm membranes before doing HPLC. Use 0.22 μm for systems with smaller particles.

Cell Culture: When filtering culture media with sera, use cellulose acetate membranes that don’t adhere to proteins well.

Performance Influencers & Best Practices

Cleaning the membrane properly makes it last a lot longer. The best ways to clean lab membranes are:

- Use the proper cleaning chemicals for the sort of membranes you have

- When you clean, ensure the pH levels stay in the right range.

- You should change the pressure according to what the manufacturer says.

- Replace membranes that have less flow or retention.

Pre-filtration makes things work better. Before final filtering, use glass fibre pre-filters on samples with a lot of solids.

The design of the system is important. Suppliers of lab-scale membrane systems often suggest certain setups based on how you want to use them.

Why Choose Sanitech Engineers Pvt. Ltd. Lab Systems

Sanitech Engineers Pvt. Ltd. knows what the labs need. Our membrane systems for the lab work consistently and don’t need much maintenance. We offer full solutions, from choosing the right membrane to starting up the system.

Our technical team can help you pick the best membrane for your needs. We offer pilot testing to make sure that everything works before we roll it out fully.

Sanitech Engineers Pvt. Ltd. makes sure that your membrane system fulfills all of your exact criteria by using their proven knowledge in pharmaceuticals, biotechnology, and research.

Our lab scale system is a scale down version of the fully functional commercial system. All the components make wrt pumps, motor, membranes, valves, etc. which are to be used at commercial scale are used at lab scale to avoid any surprises later

Conclusion

The right membrane can affect how your lab functions. You gain greater results, more efficiency, and reduced costs when you make the proper choice. Don’t let choosing a membrane slow down your study.

Are you ready to make your lab’s membrane filtration better? Sanitech Engineers Pvt. Ltd. professionals are ready to help you choose the best solution for your needs. Check out our membrane system solutions or specialised lab-scale systems today. Your research needs the accuracy that only the correct membrane can give.

FAQs

PVDF and PES membranes don't bind proteins and let a lot of water through, making them good for protein concentration.

Cleaning frequency varies depending on use or the load it has to process and nature of the solution. Food labs are cleaned daily, but water applications may only need cleaning every few months.

The correct membrane for your needs yields the finest outcomes. For best results, consult membrane experts.