The advancement in science and technology has increased the life span of an individual. Therapeutics which is a branch of medicine has also advanced towards prevention and treatment of an individual finally alleviating the disease. Since, majority of disease-causing microbes have become resistance to drugs, there is a need of a biomolecule which can be part of mimicking naturally signalling process. Also, if that molecule can provide less side effects yet offering targeted therapy will be a cherry on the cake.

Peptides are those class of biomolecules meeting all the above advantages experiencing a significant role in pharmaceutical and biotechnological research and development, rapidly gaining importance as a distinct and highly promising class of therapeutics. With these powers they are positioned as ideal candidates for addressing unmet medical needs and expanding treatment options.

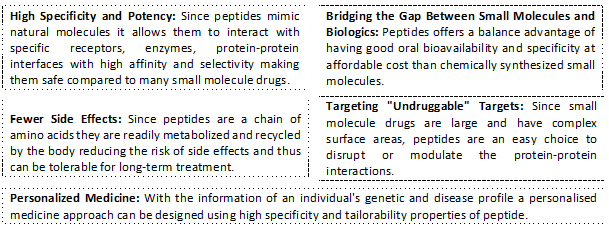

Several key attributes and advancements fueling

| High Specificity and Potency : Since peptides mimic natural molecules, they interact with specific receptors, enzymes, and protein-protein interfaces with high affinity and selectivity, making them safer compared to many small molecule drugs. | Bridging the Gap Between Small Molecules and Biologics: Peptides offers a balance advantage of having good oral bioavailability and specificity at affordable cost than chemically synthesized small molecules. |

Fewer Side Effects: Since peptides are a chain of amino acids they are readily metabolized and recycled by the body reducing the risk of side effects and thus can be tolerable for long-term treatment. | Targeting “Undruggable” Targets: Since small molecule drugs are large and have complex surface areas, peptides are an easy choice to disrupt or modulate the protein-protein interactions. |

| Personalized Medicine: With the information of an individual’s genetic and disease profile a personalised medicine approach can be designed using high specificity and tailorability properties of peptide. | |

Advances in Peptide Synthesis and Engineering

- Solid-Phase Peptide Synthesis (SPPS)

- Recombinant Production

- Peptide Modification and Formulation

- Peptide Conjugates

Key Peptides and Their Significance

Metabolic Disorders: GLP-1 agonists – Semaglutide (Ozempic, Wegovy, Rybelsus)Liraglutide (Victoza, Saxenda) Dulaglutide (Trulicity) Tirzepatide (Mounjaro, Zepbound) | Unprecedented efficacy in blood glucose control and significant, sustained weight loss. Their benefits extend to cardiovascular risk reduction. |

Peptide-Drug Conjugates (PDCs)

| Offers a highly targeted approach, similar to Antibody-Drug Conjugates (ADCs) but with the potential advantages of peptides (smaller size, better tissue penetration, potentially lower immunogenicity, easier synthesis). |

Antimicrobial Peptides (AMPs) | The desperate need for new antibiotics. AMPs offer a novel mechanism of action that could bypass existing resistance pathways. |

Oncology (Beyond PDCs) Tumor-homing peptides: (e.g., angiopep-2 for brain tumors) Immune-modulating peptides: (e.g., peptide vaccines, checkpoint inhibitors). Signalling pathway modulators: | Their high specificity can minimize damage to healthy cells, leading to better patient outcomes and fewer side effects compared to traditional chemotherapy. |

Autoimmune and Inflammatory Diseases | Offers a targeted approach to calm an overactive immune system without broadly suppressing it, which is a common issue with current treatments. |

Cyclic Peptides | They overcome some of the traditional drawbacks of linear peptides (poor stability, short half-life). Many successful peptide drugs are cyclic. |

Other applications | Cardiovascular Diseases, Neurological Disorders, Cosmeceuticals and Nutraceuticals |

Peptides once considered as niche are rapidly expanding class of therapeutics having inherent biological advantages, coupled with continuous technological breakthroughs in synthesis, purification, and delivery. This upcoming market will require advanced and efficient peptide processing solutions, an area where companies like Sanitech Engineers play a pivotal role.

In the area of therapeutics to diagnostics, peptide synthesis and purification are critical steps in the development full of challenges. This blog explores common hurdles encountered in peptide processing and presents comprehensive solutions offered by advanced separation and purification systems, specifically focusing on membrane filtration and preparative chromatography technologies, highlighting how Sanitech Engineers can be your trusted partner in overcoming these hurdles.

Peptide Processing Hurdles

Since peptides have varying sizes, charges, hydrophobicity, and propensity for aggregation, the purification is a big challenge. Some common hurdles encountered:

- Impurity Removal

- Low Yield and Recovery

- Scale-Up Challenges

- Aggregation and Solubility Issues

- Charge Variants and Isomers

- Post-Synthesis Modifications (PSM) Clean-up

- Solvent and Buffer Exchange

Unleashing the Power of Separation and Purification Systems

Membrane filtration and preparative chromatography technologies synergise in this modern separation and purification systems to provide a comprehensive toolkit to address the above-mentioned challenges. Sanitech Engineers offers a range of state-of-the-art systems designed to meet these demanding requirements.

Membrane Filtration: The Foundation for Pre-Purification and Concentration

Membrane filtration technologies offer a gentle, scalable, and cost-effective approach for initial purification steps, concentration, and buffer exchange. Sanitech Engineers provides a comprehensive suite of membrane systems including:

- Microfiltration (MF) System: Ideal for clarification of peptide solutions

- Ultrafiltration (UF) System and Tangential Flow Filtration (TFF) System:

- Impurities Removal: large molecular weight impurities and smaller molecules like salts can be removed through diafiltration.

- Concentration: dilute peptide solutions can be concentrated, significantly reducing the volume for subsequent purification steps and improving the efficiency of downstream processes.

- Buffer Exchange: With diafiltration allows efficient and gentle buffer exchange can be easily done which is crucial for preparing peptides for chromatography or final formulation. This minimizes the risk of denaturation or degradation.

- Benefits: Low shear forces with high throughput, scalable to handle large volumes and reusability of membranes contribute to lower operational costs

- Nanofiltration (NF) System: For smaller molecular weight peptides, it can be used for concentration and desalting by diafiltration.

- Lab Scale Systems: Sanitech Engineers offers a lab scale membrane system for developing process at research and development scale. It is also helping in proof of concept studies, process optimization, and small-batch production.

Learn more about Sanitech Engineers’ Membrane Systems

Preparative Chromatography: The Apex of High-Resolution Purification

Preparative chromatography remains the gold standard of the industry for achieving the high purity levels. Advanced Preparative Chromatography Systems by Sanitech Engineers provides Indian Make system meeting global standards. The offerings include:

- High-Performance Liquid Chromatography (HPLC) and Low-Pressure Liquid Chromatography (LPLC) Systems:

- Unrivalled Resolution: 95-99% purity can be achieved providing exceptional resolution based on differences in charge, size, hydrophobic nature, which is crucial for a process

- Scalability: Designed across scale of operations from lab to production, ensuring consistency and efficiency with seamless transition.

- Gradient Elution: precise isolation of target peptides with fine control over separation is possible

- Ion Exchange (IEX) Systems:

- Charge-Based Separation: charge variants, isoforms, and peptides with different numbers of acidic or basic residues can be separated.

- Complementary Purification: peptides that have similar hydrophobicity but differ in charge can use this as a complementary step with RP-HPLC.

- DAC (Dynamic Axial Compression) Columns: Available for both medium and high-pressure liquid chromatography, these columns provide excellent packing stability and efficiency for preparative separations.

Discover the range of Sanitech Engineers’ Preparative Chromatography Systems.

Process Integrated Solutions: A viable Approach

The true power lies in process integration wherein these technologies can have a seamless purification workflow. Sanitech Engineers can assist in designing a viable approach that might involve:

- Initial Clarification and Volume Reduction: Utilizing Sanitech Engineers’ Microfiltration or Ultrafiltration Systems to remove particulates and concentrate the crude peptide solution.

- Capture Step (e.g., IEX): Employing Sanitech Engineers’ Ion Exchange Chromatography Systems to bind the target peptide and remove bulk impurities.

- Intermediate Purification (e.g., HPLC/LPLC): Utilizing Sanitech Engineers’ Preparative HPLC/LPLC Systems to achieve significant enrichment and resolve closely related impurities.

- Polishing Step (e.g., HPLC/LPLC or SEC): For final high-resolution separation, removal of remaining trace impurities, and aggregate removal, leveraging the advanced capabilities of their chromatography systems.

- Final Concentration and Formulation (e.g., TFF/UF/DF): Using Sanitech Engineers’ Tangential Flow Filtration or Ultrafiltration/Diafiltration Systems to concentrate the purified peptide and exchange it into the desired formulation buffer.

The Future of Peptide Processing

Sanitech Engineers is at the forefront in providing the performing systems to meet the demand for high-purity peptides focusing on:

- Automation

- Continuous Processing

- Real-time monitoring and control

Conclusion

Peptide processing is challenging, dynamic and exciting and Sanitech Engineers stands as a leader in providing advanced and customized systems. The membrane filtration and preparative chromatography technologies can strategically be placed by researchers and manufacturers in the unit operation workflow to overcome the hurdles of impurity removal, low yield, and scalability.

The peptide market will be sustained by innovations across various therapeutic areas like GLP-1 receptor which are currently dominating due to their profound impact on diabetes and obesity. Sanitech Engineers has been instrumental in bringing these life-changing molecules from discovery to patient through processing with parallel important studies on enhanced stability, improved delivery methods (especially oral bioavailability), and exquisite target specificity.

Investing in high-quality membrane filtration and preparative chromatography systems, such as those offered by Sanitech Engineers, can lead the companies to substantial long-term cost savings from various operational efficiencies, improved product quality, reduced waste, and enhanced productivity throughout the peptide processing workflow.

FAQs

PVDF and PES membranes don't bind proteins and let a lot of water through, making them good for protein concentration.

Cleaning frequency varies depending on use or the load it has to process and nature of the solution. Food labs are cleaned daily, but water applications may only need cleaning every few months.

The correct membrane for your needs yields the finest outcomes. For best results, consult membrane experts.