MEMBRANE SYSTEMS

Ultrafiltration System

Sanitech Engineers is a leading Ultrafiltration Membrane systems manufacturer, delivering precision, scalability, and compliance across water, dairy, biotech, and chemical industries.

Nature provides many valuable molecules, which require careful extraction, separation, purification, and concentration. Both natural and synthetic molecules are processed to meet demand, often using methods that separate them by size and molecular weight through controlled pore sizes and pressure. Ultrafiltration Membrane system (UF) stands as a powerful separation technology that precisely removes particles and macromolecules from liquids using semi-permeable membrane.

UF operates using the cross-flow filtration mode and works in the cut off range from 1kDa to 800 kDa. This makes membrane ultrafiltration an ideal choice for applications requiring high precision and efficiency.

We deliver high-quality ultrafiltration membrane solutions with systems that meet all international regulatory standards using spiral/polymeric and ceramic membranes right from proof of concept to commercial scale of operations. Our ultrafiltration system designs are customized for performance, durability, and compliance across industries.

Understanding Ultrafiltration: Working Principle and Types

Ultrafiltration (UF) is a membrane separation process that removes macromolecules, proteins, and colloids while allowing water and low molecular weight solutes to pass through. UF membranes typically have pore sizes in the range of 1–100 nm (10–1000 Daltons MWCO).

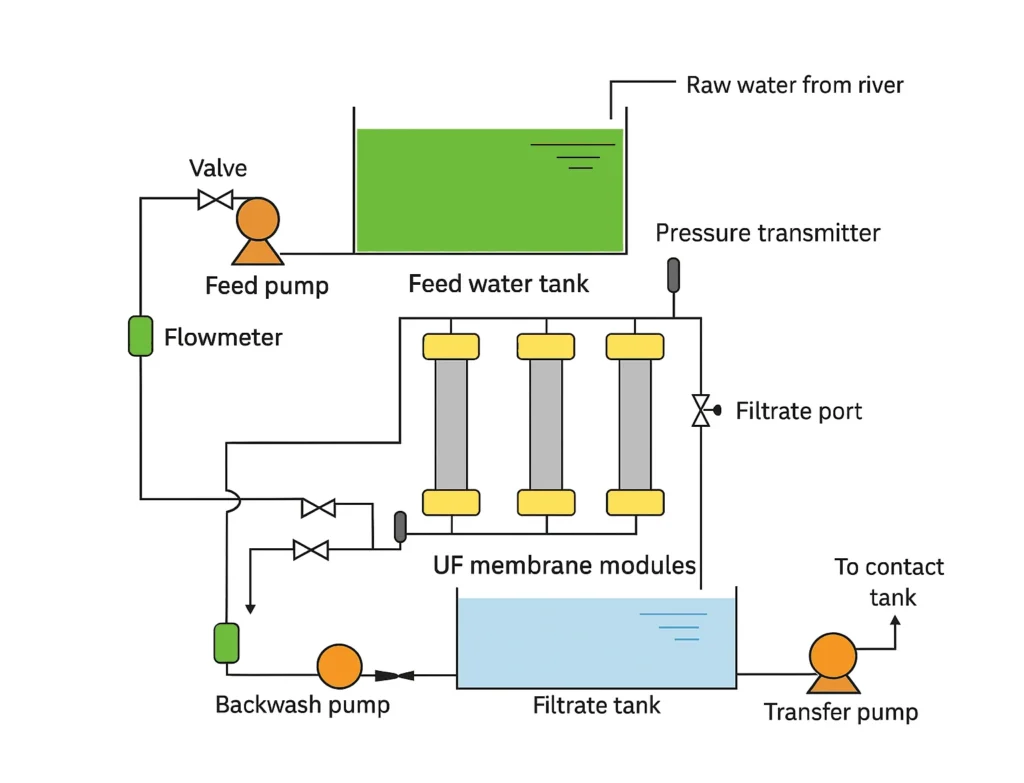

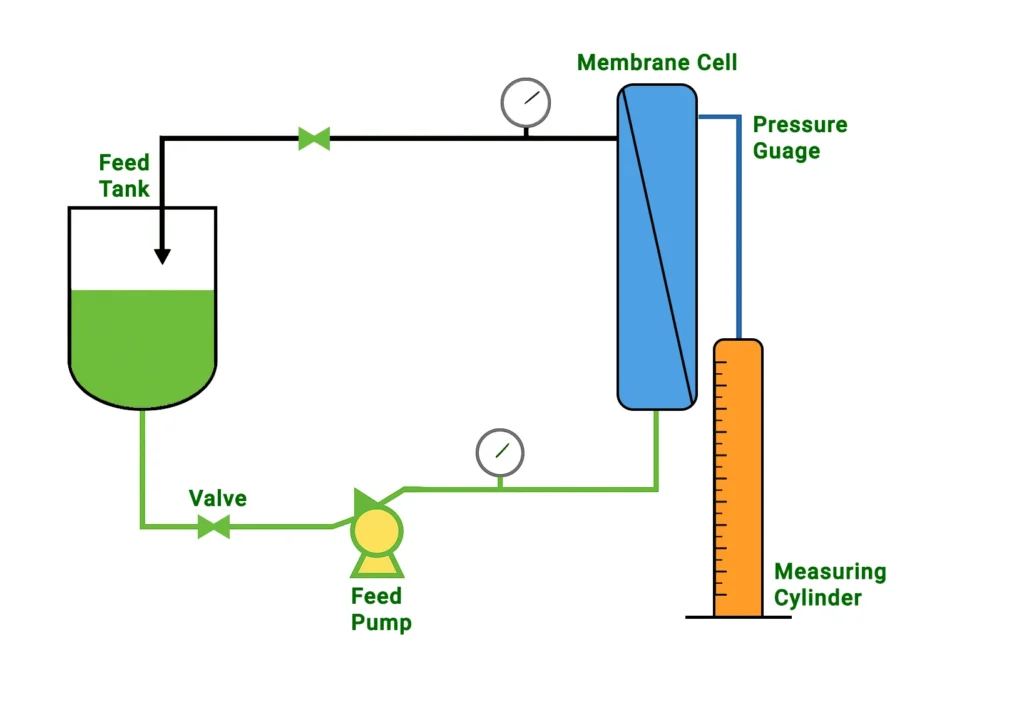

Working Principle of Ultrafiltration System

UF membranes (1–100 nm pores) retain proteins, colloids, and macromolecules while allowing solvents and salts through.

- Feed Solution Entry – The liquid is pumped into the UF unit under moderate pressure.

- Membrane Action – UF membranes act as a molecular sieve: retaining proteins, colloids, and large biomolecules while letting through salts and solvents.

- Retentate & Permeate – Retentate contains concentrated macromolecules, permeate is purified solvent with smaller solutes.

- Operating Pressure – Works typically in 1–10 bar range.

Classifications of Ultrafiltration

- Flow Configuration – Dead-End vs Crossflow UF.

- Membrane Geometry – Hollow fiber, flat sheet, spiral wound, tubular.

- Target Separation – Protein concentration, colloid removal, macromolecule fractionation.

Key Features of Ultrafiltration Systems

- Precise ultrafiltration membrane pore size of 1.0 – 800 kDa with controlled transmembrane pressure management and cross flow or tangential filtration flow mode of operation ensures maximum filtration efficiency with reduced clogging frequency. The ultrafiltration membrane size plays a critical role in achieving high separation accuracy across applications.

- Any standard makes membrane compatibility in terms of fittings: cellulose-based, ceramic, hollow fiber, PES, and PVDF materials, selected based on specific ultrafiltration membrane material and application requirement.

- Flexible module configurations: scalable architecture to handle diverse flow rates and volumes with parallel or series arrangements. Each ultrafiltration unit can be tailored for different industrial capacities.

- All-in-one maintenance for peak efficiency operation: multiple cleaning options including chemical cleaning and membrane replacement.

- Optional integration with pre-treatment processes: our microfiltration systems provide ideal upstream filtration before entering the ultrafiltration unit.

- Automated Operations: Integrated controls, sensors, and alarms ensure consistent, efficient filtration performance with sophisticated monitoring and control of pressure, flow rate, and cleaning cycles.

- Industry-compliant sanitary excellence: ensuring processed fluid safety and purity.

- Customization flexibility with compact engineering: Tailored features for targeted separation and purification process from lab to industrial scale operations.

- More than 3.5-decade old experience in making stainless steel grades (SS316, SS316L, SS304) systems: helps in gaining versatility to match application requirements. Recognized among trusted ultrafiltration membrane manufacturers in India, Sanitech Engineers delivers proven expertise and reliability.

Applications of Ultrafiltration Membrane Systems in Industries

Pharmaceutical

| Purification and concentration from API, small molecules, etc.

|

Nanomaterials

| Nanoparticle concentration and purification in advanced synthesis processes

|

Biotechnology/Biopharmaceutical

| sterile filtration, cell harvesting/separation and fermentation broth clarification, enzyme, antibody, etc.

|

Dairy

| milk standardization, bacterial removal and improved product safety, whey processing, premium ingredient production, etc.

|

Food and Beverages

| concentration and clarification of juices, sauces, wines, beers and dairy products for enhanced stability and extended shelf life while reducing transportation costs

|

Medical

| Blood plasma fractionation for therapeutic products including albumin and immunoglobulins

|

Food and Beverages | concentration and clarification of juices, sauces, wines, beers and dairy products for enhanced stability and extended shelf life while reducing transportation costs |

Pharmaceutical | Purification and concentration from API, small molecules, etc. |

Biotechnology/Biopharmaceutical | sterile filtration, cell harvesting/separation and fermentation broth clarification, enzyme, antibody, etc. |

Dairy | milk standardization, bacterial removal and improved product safety, whey processing, premium ingredient production, etc. |

Medical | Blood plasma fractionation for therapeutic products including albumin and immunoglobulins |

Nanomaterials | Nanoparticle concentration and purification in advanced synthesis processes |

A GLIMPSE OF THIS PRODUCT

Watch Ultrafiltration Membrane System in 360°

Rotate the product using mouse to experience product in 360°

FAQs

Ultrafiltration (UF) membranes are semi-permeable membranes with pore sizes typically ranging from 1–100 nm, designed to separate macromolecules from solvents. In the process industry, UF is used to retain proteins, enzymes, polysaccharides, and fine colloids while allowing water, salts, and smaller molecules to pass. This makes UF essential in biopharma (protein concentration, vaccine purification), dairy (whey and casein fractionation), nutraceuticals (plant extracts), and food & beverage (juice clarification, flavor compounds concentration) where gentle, selective separation is required without damaging sensitive biomolecules.

The function of an Ultrafiltration (UF) system in the process industry is to separate, concentrate, or purify valuable biomolecules based on molecular size. It acts as a molecular sieve, retaining proteins, enzymes, and colloids while letting solvents, salts, and small molecules pass through. This ensures high product purity, better yields, and consistency in applications like protein concentration, vaccine purification, dairy fractionation, and nutraceutical processing.

Ultrafiltration (UF) membranes in the process industry are used to separate and concentrate valuable biomolecules while removing impurities. They are widely applied in pharma and biopharma for protein and vaccine purification, in dairy and nutraceuticals for whey protein and plant extract concentration, and in biotech and specialty chemicals for clarifying fermentation broths and separating colloids.

In the pharmaceutical industry, ultrafiltration (UF) is a membrane-based separation process used to concentrate and purify proteins, enzymes, vaccines, and other biologics. It works by retaining macromolecules while allowing solvents, salts, and small impurities to pass through, ensuring product purity, sterility, and stability in drug manufacturing.

In ultrafiltration (UF), membranes are typically made from polymeric materials such as polyethersulfone (PES), polysulfone (PS), regenerated cellulose, and polyvinylidene fluoride (PVDF). These polymers are chosen for their chemical resistance, stability, and low protein binding, making them ideal for pharmaceutical, biotech, and food processing applications.