Membrane Systems

Caustic Recovery System

Sanitech Engineers is one of the Top and Reliable caustic recovery systems manufacturers and providers meeting international regulatory standards.

CIP is very crucial in any process for which chemical cleaning is the method of choice. A Clean in place System ensures thorough internal cleaning without dismantling the equipment. Caustic is majorly used in CIP as it is cheap and easily available. The CIP cleaning solutions land up in high volumes, which adds to the load on the ETP process. Caustic soda recovery offers a 3-fold advantage:

- Saving caustic and water

- Saving acid, as caustic or high pH water cannot be sent to ETP directly. Thus, it needs to be neutralised, which generates salt

- Salts need to be removed before sending to ETP

Thus, a suitable caustic recovery system that can withstand high pH conditions can help in cost-effective caustic soda recovery and recycling, reducing waste generation, lowering operating costs, and promoting sustainable practices across various industrial processes including dairy, pharmaceuticals, biopharmaceuticals, petrochemicals, pulp and paper, textiles, and metal processing.

The CIP system or spent caustic usually contains impurities and contaminants, which are removed using a specialized membrane capable of withstanding pH up to 14.0.

A well-designed caustic recovery plant can integrate seamlessly into any cip system to improve efficiency and reduce environmental load.

Understanding Caustic Recovery: Working Principle and Types

Reverse Osmosis (RO) is a high-pressure membrane separation process that removes dissolved salts, organic molecules, and impurities at the ionic level. RO membranes have a pore size of ~0.1–1 nm and a MWCO below 200 Daltons.

Working Principle of Reverse Osmosis System

High pressure forces liquid through semi-permeable membranes (~0.1–1 nm), removing dissolved salts and impurities.

- Feed Solution Entry – High pressure is applied to push the liquid against the RO membrane.

- Membrane Separation – The semi-permeable membrane blocks salts and dissolved solids while allowing only solvent molecules to pass.

- Retentate & Permeate – Retentate is the concentrated brine/reject, permeate is the purified solvent.

- Operating Pressure – Works typically at 10–80 bar depending on feed concentration.

Classifications of Reverse Osmosis

- Membrane Types – Thin-film composite (TFC), cellulose acetate.

- Designs – Spiral wound, hollow fiber.

- Operating Range – Low-pressure RO, brackish water RO, high-pressure RO.

Advantages of Caustic Recovery System:

- Energy-efficient processing technology

- Minimal operating and maintenance costs

- Versatile systems adaptable to various product applications

- Built-in SIP/CIP capabilities for comprehensive cleaning

- Sanitary system design for hygienic applications

- Zero effluent discharge for environmental compliance

- Compact, skid-mounted systems with minimal footprint

- Superior CapEx and OpEx compared to traditional separation methods

- Multiple membrane options across MF, UF, NF, and RO technologies with various materials of construction and module designs for specific process requirements

Applications of Caustic Recovery System

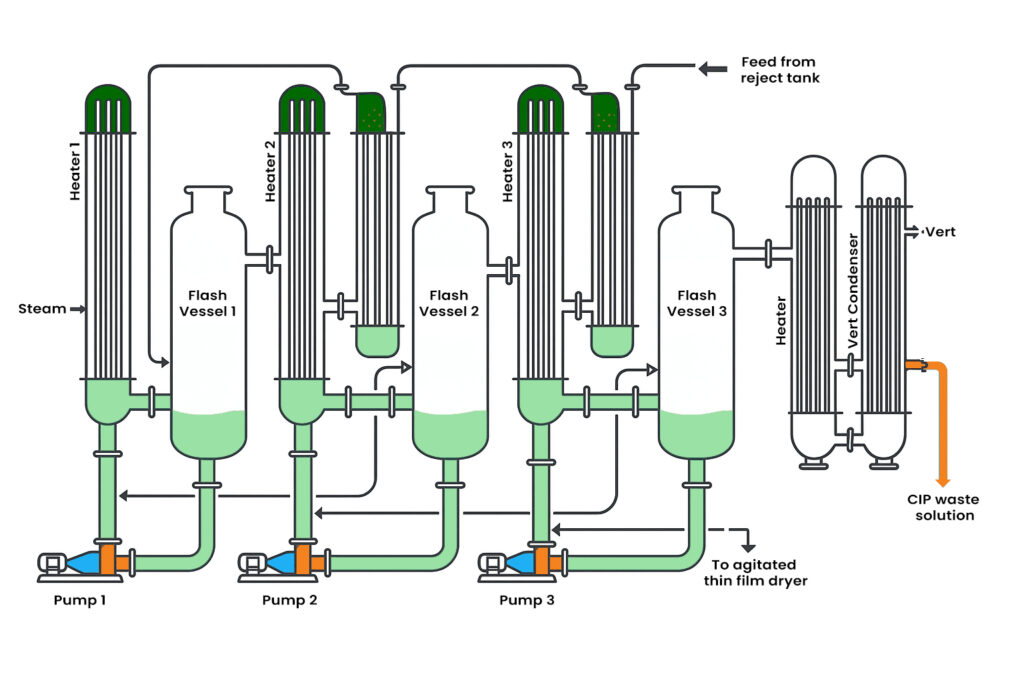

- Caustic recovery CIP waste solution for efficient recycling and reduced environmental load

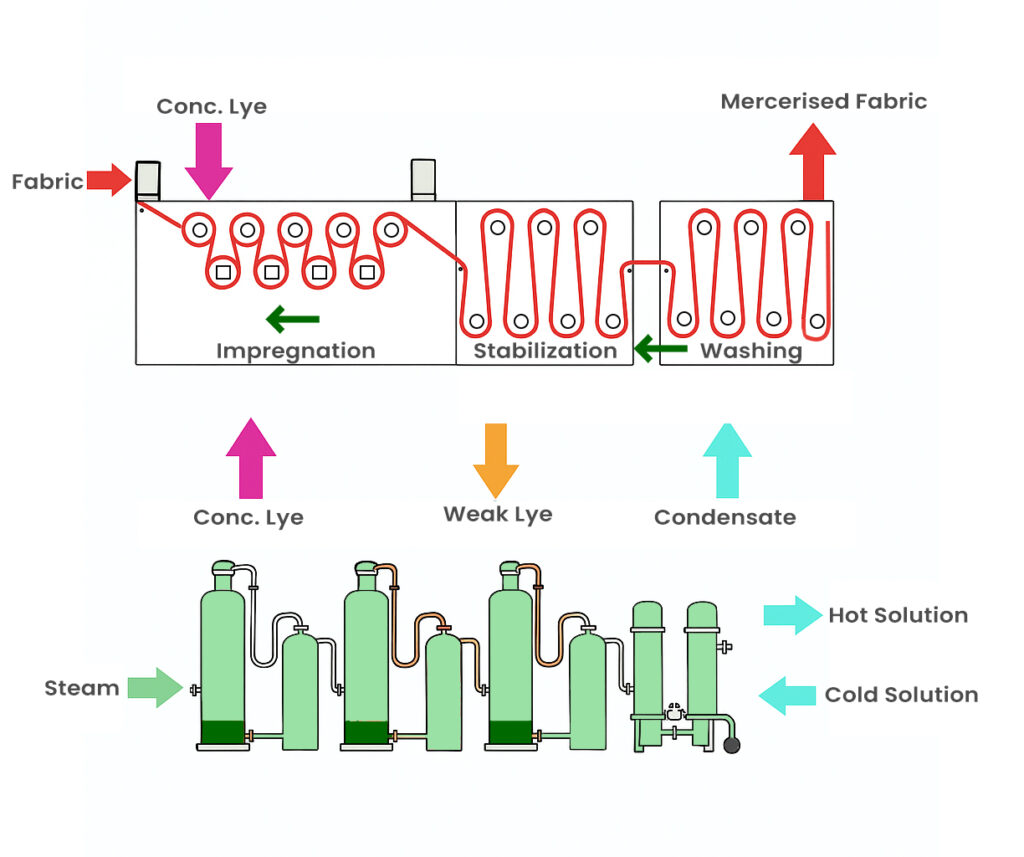

- Suitable for dairy, food & beverages, and textile industries

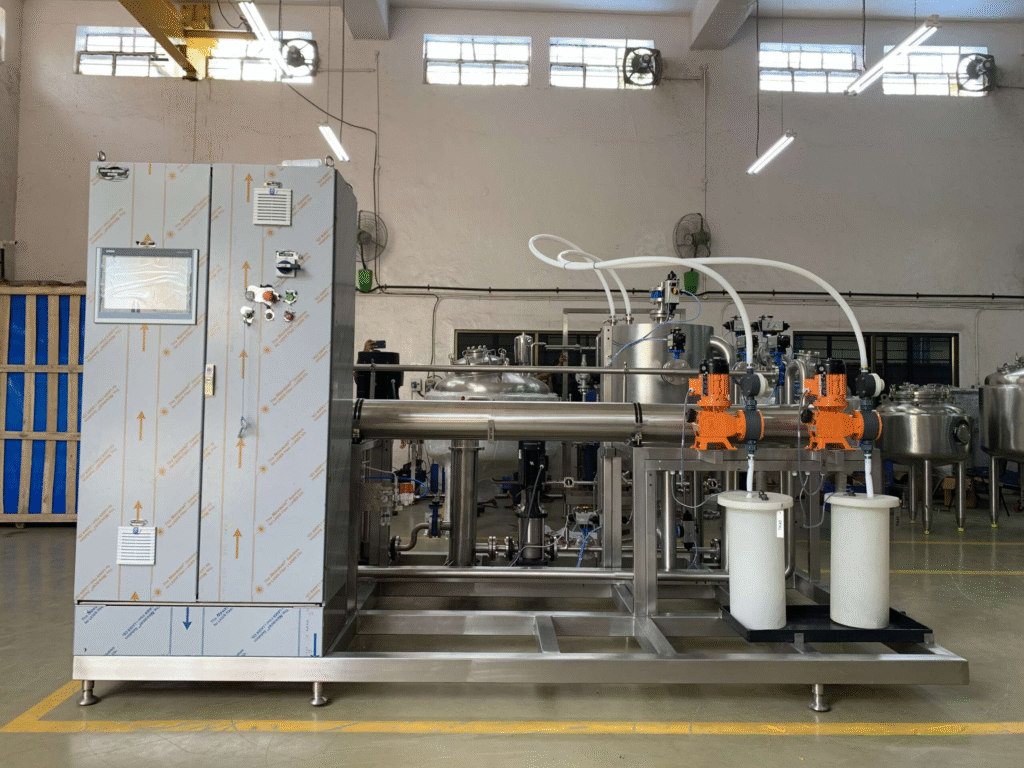

A GLIMPSE OF THIS PRODUCT

Watch Caustic Recovery System In 360°

Rotate the product using mouse to experience product in 360°

FAQs

A caustic recovery system (CRS) is an industrial setup designed to reclaim and reuse spent caustic soda (NaOH) solutions that are used in cleaning, textile mercerization, or other process applications. Instead of discarding the caustic after it becomes diluted or contaminated, the CRS concentrates and purifies it through membrane filtration, evaporation, or other separation technologies, allowing industries to cut chemical costs, reduce wastewater load, and improve sustainability.

The caustic recovery process reclaims used caustic soda (NaOH) from industrial operations by filtering out impurities and concentrating the solution through membrane filtration or evaporation. The purified caustic is then reused in processes like textile mercerization, pharmaceutical cleaning, or food production. This reduces chemical costs, minimizes wastewater, and supports sustainable manufacturing.

The full form of CRP plant is Caustic Recovery Plant.

It is used to recover and recycle caustic soda (NaOH) from industrial processes, mainly in textiles, pharmaceuticals, and food industries, to reduce chemical consumption and environmental impact.