Membrane Systems

Lab Scale System

Sanitech Engineers is a trusted provider of lab-scale systems for R&D applications, engineered to meet international regulatory standards.

A cost-effective process and successful commercial scale operating plant demands a full proof process developed at R&D/lab scale. For conducting studies at R&D one needs a partner who can understand the process and have an equipment which can handle small volumes and process it to get the desired quality in each unit operation.

Also, the R&D scale system needs to be versatile to be used for processing multiple products having different applications as well as process multiple unit activities. To have such a compact and long-lasting quality system which can help R&D cater excellent products for the organization, designing lab scale systems from decades for separation and purification experience across diverse products and clients has been a USP of Sanitech Engineers.

These systems are specifically designed for evaluating membrane process feasibility and determining their applicability to meet specific separation and purification objectives.

Data collected during lab-scale process development can be optimized and linearly scaled up for production-level implementation. Our experienced professionals have meticulously designed these lab-scale systems using proven scale-down design principles, creating compact systems capable of accommodating both inorganic and organic membranes.

Industries

Understanding Lab Scale: Working Principle and Types

Lab Scale Systems are compact membrane filtration setups designed for research, testing, and pilot studies. They allow simulation of industrial separation processes at laboratory scale using smaller volumes.

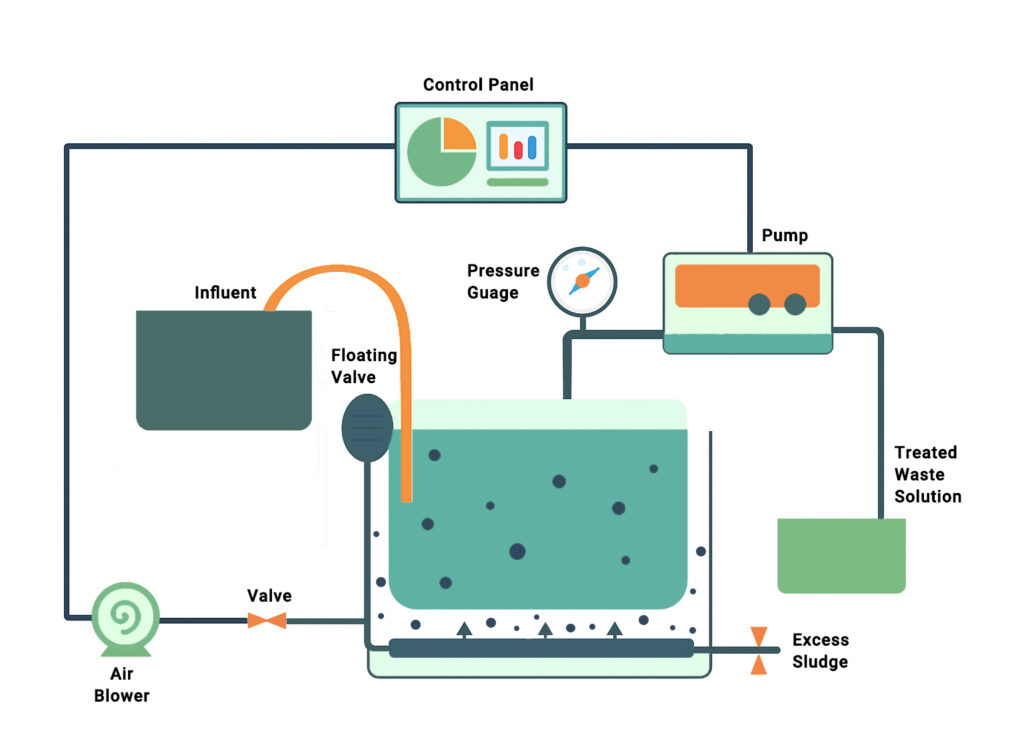

Working Principle of Lab Scale Membrane System

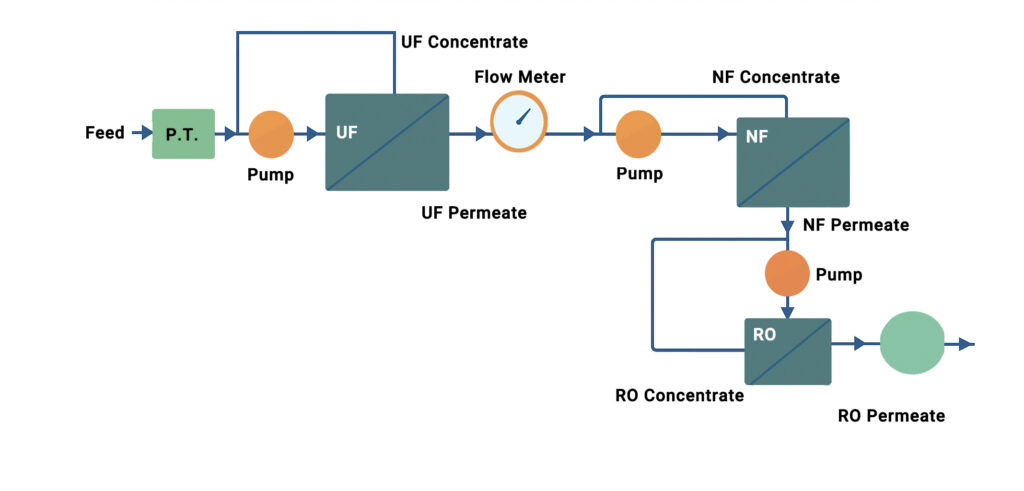

Compact membranes (MF, UF, NF, RO) filter small volumes for testing and process simulation.

- Feed Entry – Small volumes of solution are introduced.

- Membrane Action – Operates with different membrane types (MF, UF, NF, RO) depending on the experimental requirement.

- Output – Provides permeate and retentate streams for analytical testing and scale-up evaluation.

- Operating Range – Flexible pressure and flow controls for experimentation.

Classifications of Lab Scale Systems

- Based on Membrane Type – MF, UF, NF, RO testing units.

- Based on Design – Stirred cell, crossflow cell, bench-scale modules.

- Based on Purpose – Product testing, process simulation, pilot trials.

Lab Scale System Features

- Compact skid-mounted design in stationary or portable configurations

- Minimal laboratory footprint requirements

- Universal membrane module support including hollow fiber, spiral, cassette, and tubular configurations

- Integrated CIP functionality for comprehensive cleaning

- Low hold-up volume with 1-5L working volume, expandable to 20L

- Complete SS316L wetted area construction

- Pumps: Diaphragm pump (0-25 bar) and centrifugal pump (0-4 bar)

Applications of Lab-Scale Membrane System

- Proof of concept studies for validating membrane performance before full-scale deployment

- Suitable for R&D, pilot testing, and process optimization in various industries

FAQs

The lab scale refers to small-scale experimental setups used in research and development before moving to pilot or industrial production. Our Lab-Scale Membrane Systems are designed to simulate real filtration processes (UF, NF, RO) at laboratory level, allowing industries to test, optimize, and validate their applications cost-effectively.

The mother liquor (or spent liquor) is the liquid that's left after you take out a part of it. This happens when you filter something or when you make crystals form in the liquid.

Mother liquor demineralization is the process of removing salts and impurities from the residual liquid left after crystallization (like lactose mother liquor in dairy). Using our Lab-Scale Membrane Systems, this process can be tested and optimized at R&D level, helping industries like dairy, pharma, and biotech improve product yield and quality before moving to full-scale production.

In a membrane filtration lab, lab data refers to the performance results generated during proof-of-concept studies, such as flux, retention, concentration factor, and cleaning behavior. This data demonstrates how a membrane system will perform under actual process conditions, helping customers make informed decisions before scaling up to pilot or industrial equipment. Thus, Performance Data, Process Data, Application-Specific Data, Comparative Data are generated