Membrane Systems

Nanofiltration System

Sanitech Engineers is a trusted manufacturer of Nanofiltration System in India, delivering durable, high-performance solutions tailored for critical operations and international compliance.

The most versatile amongst all the membrane filtration types is nanofiltration system solutions (NF), which is positioned between ultrafiltration and reverse osmosis in terms of selectivity. This nanofiltration process not only separates the molecules based on molecular weight/size but also based on the charge. Hence, it works on a dual principle of separation. Typical molecular weight cutoffs for NF (e.g., separates molecules of 200–1000 Da) make it ideal for selective filtration needs.

Widely utilized across biotechnology, dairy, pharmaceutical, nutraceutical, and food processing industries, nanofiltration provides precise separation control that enables concentration and purification of target substances while retaining desired components in treated liquids. This makes the nanofiltration membrane for water treatment and other liquid processing applications extremely valuable in both industrial and research settings.

We not only offers advanced nanofiltration membrane system in India, but also provides a comprehensive portfolio of membrane technologies, ranging from Microfiltration to Reverse Osmosis. Tailored for critical applications in water treatment, pharmaceuticals, food processing, and more.

Understanding Nanofiltration: Working Principle and Types

Nanofiltration (NF) is a semi-permeable membrane process designed to separate small organic molecules and multivalent ions while allowing monovalent salts to pass. NF membranes have a pore size of ~0.5–2 nm and a molecular weight cut-off (MWCO) between 200–1000 Daltons.

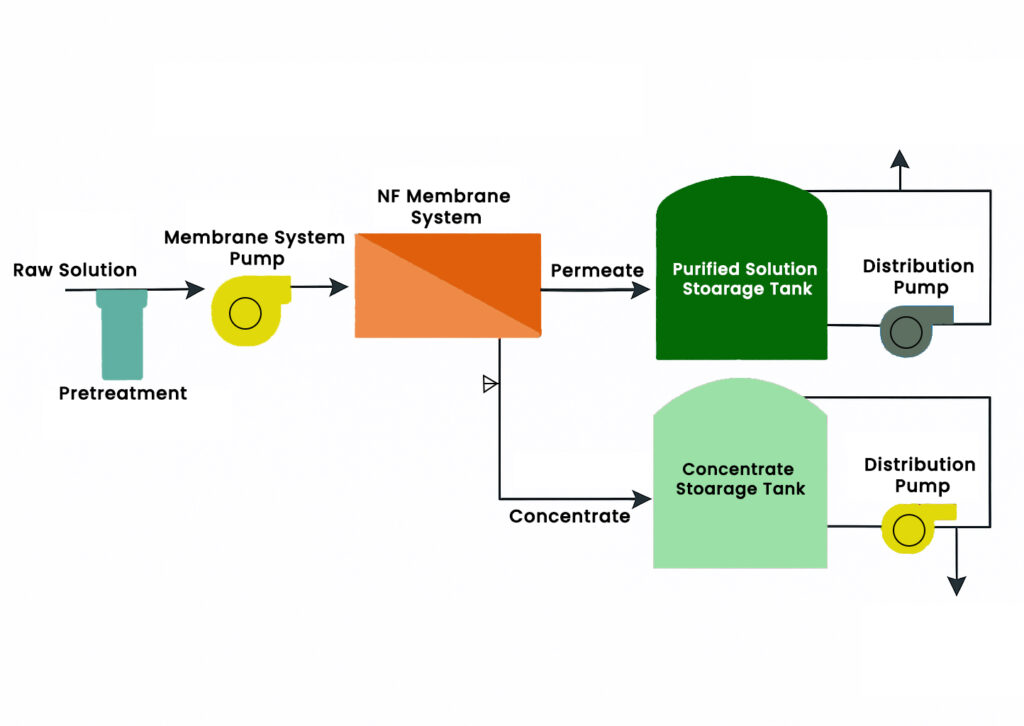

Working Principle of Nanofiltration System

NF membranes (~0.5–2 nm) selectively block multivalent ions and organics while permitting monovalent salts.

- Feed Entry – Liquid enters the NF system under higher pressure.

- Membrane Separation – NF membranes selectively retain divalent and multivalent ions, larger organic molecules, and some salts.

- Retentate & Permeate – Retentate is concentrated with rejected solutes, permeate is softened liquid with reduced contaminants.

- Operating Pressure – Typically works in 4–30 bar range.

Classifications of Nanofiltration

- Membrane Type – Thin-film composite, polyamide-based.

- Design Geometry – Spiral wound, hollow fiber, flat sheet.

- Target Separation – Divalent ion removal, selective organic separation.

Technical Excellence in Nanofiltration Systems

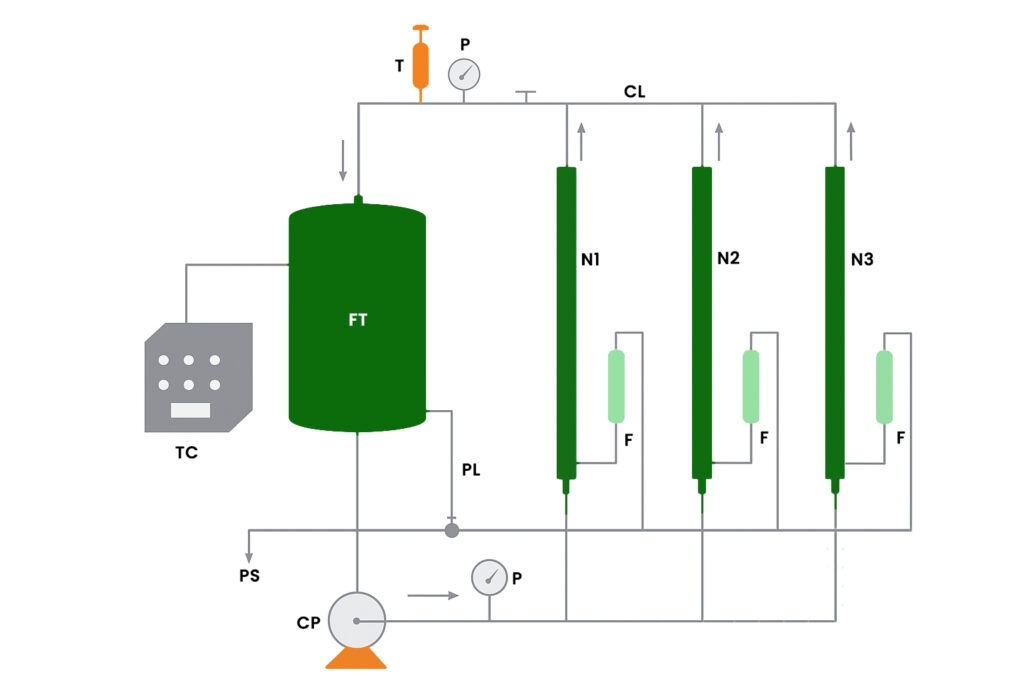

- Precise membrane pore size of 100 – 800 Da with controlled transmembrane pressure management and cross flow or tangential filtration flow mode of operation ensures maximum filtration efficiency with careful separation control

- Thin-film composite material: polyamide and specialized polymeric materials enable selective transport based on both size and charge characteristics

- Controlled pressure mechanism: filtration performance under regulated conditions while preventing fouling

- Precise deashing: Unique capability to remove minerals which have multiple charges like ions of calcium, magnesium, sulphate, etc. while allowing single charge ions like sodium, chloride, etc. to pass

- Robust membrane: withstand various pH conditions, supporting diverse industrial applications including acid and alkali recovery

- Optional integration with pre-treatment processes: our microfiltration and ultrafiltration systems provide ideal upstream filtration

- Intelligent Automation: Advanced control systems monitor and adjust operating parameters for consistent, efficient performance

- Versatile Design: Compact systems scalable from laboratory research to full industrial production

Strategic Applications of Nanofiltration Systems

Pharmaceutical

| Purification and concentration from API, small molecules, etc. |

Biotechnology/Biopharmaceutical

| concentration of valuable compounds including proteins, peptides, enzymes, and natural extracts |

Nanomaterials

| Nanoparticle concentration and purification in advanced synthesis processes

|

Dairy

| product desalting/demineralization

|

Process streams

| Selective removal of multivalent ions including calcium and magnesium, elimination of harmful contaminants including pesticides, herbicides, and pharmaceutical residues, colour-causing substance removal |

Personal care

| Micropollutant removal

|

Food and Beverages

| concentration of juices, sauces, wines, beers and dairy products for enhanced stability and extended shelf life while reducing transportation costs, beverage debittering

|

Recovery

| valuable component recovery from industrial effluents, acid and caustic concentration and separation for reuse

|

Food and Beverages | concentration of juices, sauces, wines, beers and dairy products for enhanced stability and extended shelf life while reducing transportation costs, beverage debittering |

Process streams | Selective removal of multivalent ions including calcium and magnesium, elimination of harmful contaminants including pesticides, herbicides, and pharmaceutical residues, colour-causing substance removal |

Pharmaceutical | Purification and concentration from API, small molecules, etc. |

Biotechnology/Biopharmaceutical | concentration of valuable compounds including proteins, peptides, enzymes, and natural extracts |

Dairy | product desalting/demineralization |

Nanomaterials | Nanoparticle concentration and purification in advanced synthesis processes |

Personal care | Micropollutant removal |

Recovery | valuable component recovery from industrial effluents, acid and caustic concentration and separation for reuse |

A GLIMPSE OF THIS PRODUCT

Watch Nanofiltration Systems Product in 360°

Rotate the product using mouse to experience product in 360°

FAQs

A nanofiltration (NF) system is a membrane-based separation process that operates between ultrafiltration and reverse osmosis. It removes divalent and larger ions, organic molecules, and contaminants while allowing most monovalent salts to pass. In industries, NF is widely used for product concentration, partial demineralization, and purification of process streams.

The principle of nanofiltration is size exclusion and charge-based separation. NF membranes have pore sizes around 0.001 microns, which allows water and small monovalent salts to pass while rejecting divalent and larger ions, organics, and contaminants. This makes it ideal for selective separation where partial demineralization or concentration is required.

A nanofilter works by forcing liquid under pressure through a semi-permeable membrane with nanometer-sized pores. These pores allow water and small monovalent salts to pass through while blocking divalent salts, organics, and larger molecules. The result is a stream of purified permeate and a concentrated reject stream containing the removed substances.

In biotechnology, filtration is widely used for sterilizing culture media, buffers, and reagents by removing microorganisms and particulates. It is essential in harvesting cells, clarifying fermentation broths, and purifying biomolecules like proteins, enzymes, and nucleic acids. Filtration also plays a key role in downstream processing, ensuring product purity, consistency, and compliance with regulatory standards.

Nanofiltration (NF) is applied in industries to separate divalent and larger ions while allowing monovalent salts to pass, making it useful for partial desalting and concentration processes. In pharmaceuticals and biotech, it is used for solvent recovery, API purification, and removal of endotoxins. In food and nutraceuticals, NF helps in demineralizing whey, concentrating bioactive peptides, and clarifying plant extracts.